Usually this is formed on a 60 degree V-block with the point rounded to match the required LE radius. This rounding is essential. About 2 layers of 35 gsm Kevlar would be a good starting point for F1A. What comes off the form is a bit like wet cardboard and only gets stiff when its glued round a set of ribs and spar. This method needs a close rib spacing to maintain section shape and stiffness. Fitting a LE can help keep the ribs in place and aid assembly.

You can form carbon shell on a V-block, but it must be formed into a D-box within 24-36 hours of making it, while the epoxy is cured enough to handle but still 'green' and capable of holding a shape when its bent. The rib and LE requirements are essentially the same as for Kevlar formed on a V-block. The result will be stiffer than the Kevlar equivalent.

This is my preferred method. Very few ribs are needed depending on the thickness of the shell. Another justification of this approach is that normal 1.5 mm balsa ribs in a D-box split the first time the wing gets hit and contribute little thereafter. My few ribs are made from balsa ply and so will not split but will still weigh less.

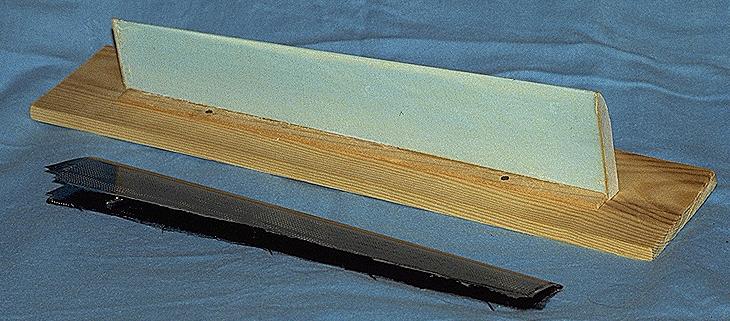

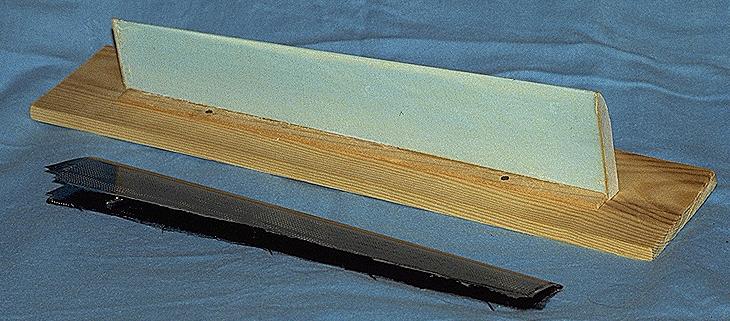

You are going to lay up your D-box material between two release films, drape this over the LE form and pop the lot into your vacuum bag and suck. Of course you will put heavy mylar outside the layup (to get a better finish on the outside of the D-box) and bleeder cloth over this to distribute the vacuum properly inside the bag. There are variations on this basic plot:

You can then calculate weight; double the total cloth weight to allow for epoxy. Carbon cloth is relatively thick - its difficult to find anything under 80 gsm. Always use the cloth at 45 degrees - the D-box is there as a torsion member not for bending load. A typical F1A D-box is 2 - 3 layers of 80 gsm carbon or one of 190 gsm cloth. The cloth is always used with its tows at 45 degrees to the chord line and its important to use cloth with equal amounts of carbon in each direction. If this is not the case you will get warps.

I'm using 2 layers 83 gsm plus a single inside layer of Russian unidirectional material, which weighs 120 gsm, with fibres running chordwise as a sort of distributed rib for the inner panels. The tip panels have a single layer of 83 gsm cloth plus the inner layer of unidirectional Russian carbon. This way I only need a rib every 150 mm within the D-boxes.

The inner panel D-boxes come out at 0.38 mm thick and the tips at around 0.28 mm.

F1A tails (especially if they are the Woebbeking section) often use a single layer of 83 gsm carbon to make a narrow (10% chord) D-box. I haven't thought about F1J D-boxes yet, but would probably use 1 layer of 83 gsm cloth as a starting point. Have a close look at Randy Archer's Xenon design. Its light and strong and uses a carbon D-box. Also check out what the current F1B fliers are using as that should suit an F1J rather well.

Its very difficult to get the epoxy down to only 50%. You need to put on just barely enough to wet out the cloth and then squeegee and roll and blot with kitchen towels until you can't get any more out. Do this between layers. Weigh the cloth before you lay it up. Weigh the mylar if you're an accuracy fiend. Weigh the complete D-box. Calculate the epoxy percentage and you'll probably still find you've got 60% epoxy. Maximum strength results when the fibre:epoxy weight ratio is 50:50. Epoxy is heavy: excessive amounts of it add nothing to the D-box except weight.

You need a full-depth carbon spar to close the D-box. In all models apart from gliders I'd suggest using a piece of medium 3 mm balsa (grain running spanwise), tapered in thickness with 0.2 to 0.4 mm pre-formed carbon flanges stuck on the top and bottom edges with thick cyano or epoxy. The flange thickness is dependent on the size and weight of the model. The spar needs at least one carbon web. For a light model this need be nothing more than a single layer of 80 gsm carbon cloth at 45 degrees compacted and laminated onto the rear surface. Heavier or faster models should have the entire spar enclosed in woven carbon sock or wrapped in Kevlar thread. See Appendix B for more information on the sock.

This stuff has a fairly loose weave, so it distorts and snags really easily. While you can cut the sock with sharp workshop scissors this will not work for the cloth. I think the best way is to use a rotary cloth cutter and steel straight-edge and cut it on a self-healing cutting pad.

A sharp Swann-Morton or scalpel blade is almost as good as the rotary cutter, but the latter is particularly good because it rolls over the cloth it is cutting rather than dragging on the fibres. I think the cutting pad stops the cloth from distorting because the fibres get dragged down into it's surface and so are anchored before they are actually sliced apart. As a result you are less likely to snag or tear any delicate of loosely woven material if you cut it on a cutting pad.

Some people put masking tape on the cloth and cut through it. This is essential for Kevlar, but you need to take more care with carbon. If you try to peel dry masking tape off you'll make a horrible mess of the cloth. However, I've found out that if you dribble nitrate dope thinners onto the masking tape and wait 30 seconds it can be lifted off without disturbing the weave. This technique will even remove masking tape that has been left on the inside of a carbon D-box while it was wetted out with epoxy and cured in a vacuum bag. Don't ask how I know that....