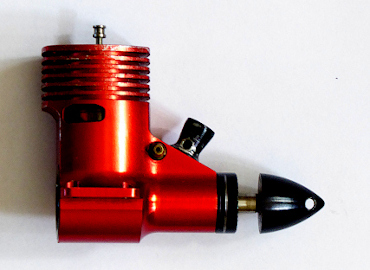

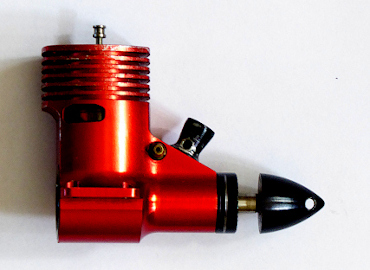

The Shuriken 061 FISE, #50065. This example has seen some use. The venturi has been drilled on the right side to take a flood-off inlet.

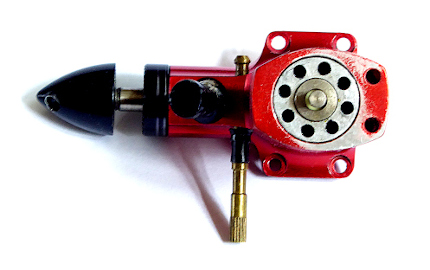

The Shuriken multi-purpose wrench.

|

|

The Shuriken 061 FISE, #50065. This example has seen some use. The venturi has been drilled on the right side to take a flood-off inlet. |

|

|

The Shuriken multi-purpose wrench. |

The Shuriken was the first really powerful F1J engine to be manufactured. At 62.1g in standard trim it is the lightest of the hot F1J engines.

It is a lovely bit of engineering and is still the only American F1J engine to have been made.

My Mk 1 FISE 061, serial number 50065, is pictured above. It did 26000 rpm on an APC 6x2 propeller. This was vastly over propped: the engine's peak output was 0.35 bhp at 35,000 rpm and it was stressed for 40,000 rpm. However, the smaller props needed for the high revs produced considerably less static thrust, and hence an inferior climb compared with the APC 6x2.

Mark Panos had a late Mk 1 FISE 050, serial number 50214, which he used for 1/2A Pylon Racing. He reports that on 20% nitro it turned a 5 x 3 Tornado at 32,000 - 33,000 rpm on the ground and really unloaded in the air. One of his friends bought a Mk 2 FISE 050 but it was disapointing: on the same fuel and prop it was 4000 rpm down at only 28000 - 29000 rpm.

|

|

|

All four variants used a Glo-Bee head insert held in with an alloy clamp ring, which screwed into the unitary crank case. The Glow-Bee plug formed the entire cylinder head: the clamp ring sealed it onto one or more copper shims on the liner's top flange, which locates on the top of the crank case bore. This is a close fit on the liner and is near the top of the finned part of the crank case.

The cylinder was ABC technology with a brass liner in which the transfer passages and ports were formed by removing vertical sections of the liner: the piston skirt forms the inside wall of the transfer passages and the crank case bore forms their outside wall. As the liner was thinner in the 061 versions, its quite possible that their breathing was restricted compared with the 050s.

The piston was extremely light and made from a very soft aluminium alloy containing 40% silicon. My 061 required a new piston after the plug dropped an element, but the chromed bore was undamaged: a real tribute to the production quality.

The venturi was a screw-in unit whose bore was selectable to suit the engine's application. It had three equally spaced peripheral jets fed by an annular gallery machined into the venturi body above the thread and sealed by a shoulder that screwed down onto the crankcase surface. The brass needle assembly, with a very fine thread on the needle, was remote from the venturi with a narrow bore connecting it to the fuel gallery. It was pressed in after carefully aligning the fuel exit hole with the transfer bore. The bore's diameter was reduced to a minimum to control surging: with ear defenders on you could hear the engine note wavering slightly due to residual surging, though it was too slight to be seen on a digital tachometer or heard by unprotected ears.

The crank case was NC machined from a single piece of alloy bar stock to very fine tolerances and then anodised inside and out.

The backplate was a screw-in alloy unit with a central pressure tap. This was blind when supplied: so the purchaser used a 0.6 mm drill to open it to the crank case if they wanted to use a crank case pressurised fuel system and/or flood-off.

The multi-purpose wrench shown below the engine was used to unscrew the backplate, to remove the Glo-Bee clamp ring and to unscrew the spinner.

|

|

|

| Glo-Bee head, clamp ring, copper shim on top of liner | Crank case internals.the The right-hand transfer passage gas entrance is just right of the connecting rod, extending up behind the piston skirt. The exhaust port is angled back about 45 degrees on the right side of the engine, so the entire liner is rotated 45 degrees anti-clockwise by comparison with a conventional setup. |

Needle, showing its blunt tip, shallow taper and very fine threads. |

The Mk 1 was produced as a single batch of 250 engines, made up from a mix of 050 and 061 capacities in both FISE and FIRE formats. They were anodized red with BV engraved on the left side of the NC machined case, which was a work of art. The serial number is engraved on the underside of the left mounting lug. The clamp ring was bare metal so there was good electrical contact with the glow clip. This version had two design faults:

The Mk 2 was outwardly identical except that it was anodized gold with VE engraved on the left side of the NC machined case. Serial numbers, starting at 50500, were machined into the opposite side of the case. The liner was revised: the transfer ports were machined into the outside of the liner rather than retaining the cut away vertical sections of the Mk 1. As the liner wasn't appreciably thicker than on the Mk 1, this probably restricted its breathing. Other revisions were a change to an inferior liner hardening technology and an excessive reduction of the bore's taper. As a result these engines wore out fast and ran considerably slower than the Mk 1.

Production ceased when the partnership of Fred Baldwin and Jim van Arsdall broke up: collectors probably have most surviving Shurikens by now.

|

|

A new Shuriken 061 FISE.

|

During 2005 a small number of new Shuriken 061 FISE engines appeared on eBay. I've seen three so far: there may have been more. The accompanying text for the third auction read:

You are bidding on a new in box with papers and wrench Shuriken AAC 06 competition model airplane engine. It was designed by Fred Baldwin and assembled by Glenn Lee.

These Shurikens have not all been auctioned by the same source, though the wording of the advertisements has been quite similar. At least two of the sellers have been fairly bigtime dealers in collectable model engines. Neither appears to be either Fred or Glenn. All have a modified crank case: the overhanging fins at the rear have gone, all four vertical edges of the head fins are rounded off and the logo on the left of the case is just B. The colours are much brighter and different from the original engines: two cases have been violet and the third was electric blue, all the backplates have been gold with gold or black spinners and intakes. The first two had gold, flush mounted head clamp rings and heads adapted for Nelson plugs. The third seems to be fitted with a custom button head and a black head clamp that stands proud of the case. The wrenches look like they were made as part of the original, cherry red, batch of engines. The boxes may also be from the original production run because the first two were described as being supplied in "shop soiled boxes". All three have had the same blue-grey plastic ring fitted in place of a prop. None of the production engines were supplied with this item. All three engines have been described as AAC, while both production batches had ABC cylinder technology.

|

|

A Shuriken 061 FISE assembled by Glenn Lee.

|

Glenn Lee is responsible for the production of these engines. Greg Kamysz, who flies electric RC but likes engines, met him when he was selling a couple of examples at a swap meet. Glenn said that he purchased the left over parts when Fred Baldwin went out of business and that he has a number of crankcases. He will be making missing parts to complete those engines. My best guess is that Fred was planning a limited run of what would have been a Mk 3 Shuriken under a Baldwin logo but never completed them.

Greg expects all these engines to end up in collections. Judging by the prices paid for them I think he's dead right. I don't know what the first to appear on eBay sold for, but the second and third fetched $US 300.00 each. By comparison the Cyclon 061, which at the time of writing in early 2006 is probably the best current F1J engine, is available for $US 190.00.

Jeff Cook, who supplied information about production batch sizes and identification marks, worked for Jim VanArsdall on the Shuriken project as a consultant and machinist with responsibility for optimising the cylinder porting. He tells me that both he and Jim still have a fair inventory of parts. They are happy to supply them to anybody who needs replacements. You can contact Jeff via the e-mail link at the start of this paragraph.

In addition, other people bought parts at the same auction as Glenn Lee. Some of these have appeared on eBay, but their whereabouts and availability are not known.